Customer Profile

A group of students at HTL 3 Rennweg, a college of engineering for students aged 14-19 in Vienna, Austria, envisioned building a robotic arm for their diploma project. Confronted with the problem of fabricating such a complex model, they contacted BE3D. The company provided the students with a versatile, user-friendly 3D printer, which enabled them to build a successful prototype.

Challenge

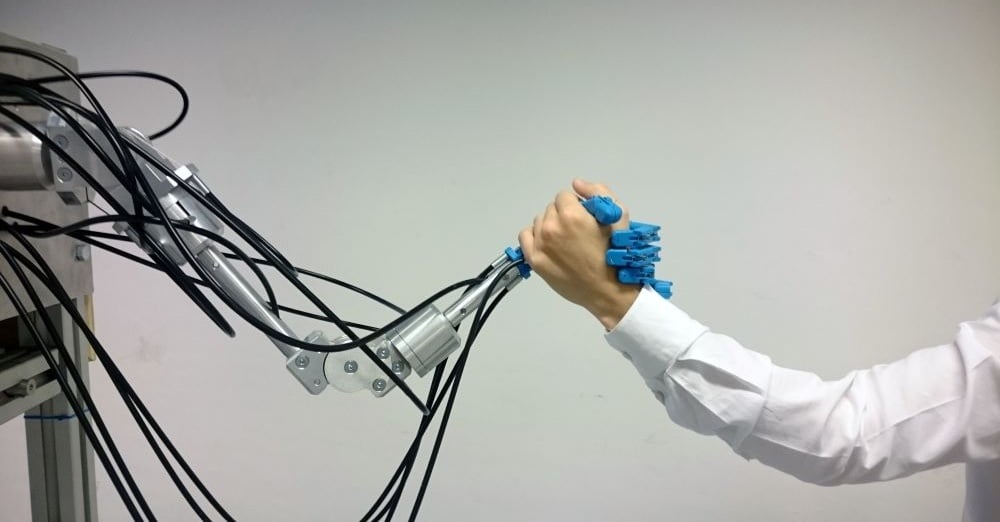

Inspired by the Iron Man movies, students use 3D printing to bring their vision of a robotic arm to life.

Building a robotic arm and hand was an ambitious project for students Paul von Ahsen, Nino Wegleitner, and Gernot Keuschnig. Inspired by the Iron Man movies, the students wanted to create a working prototype that would mimic the motions of a human arm for capture by a special 3D camera. In the real world, a robotic arm could be used by people who handle dangerous or toxic materials, such as explosives or radioactive substances.

The project imposed some special challenges – a working replica of something as complex as a human arm and hand had to be created on a student’s budget. The students began researching 3D printers that could print intricate parts that would fit together exactly and operate smoothly. When the students contacted Y Soft and saw the BE3D printer in action, they knew they had found the answer.

Solution

The YSoft BE3D 3D printer is a user-friendly, high-quality, entry-level 3D printer ideal for product designers, schools, architects, interior design studios, hobbyists, fashion designers, and households. The sturdy, fully-enclosed industrial design and the ability to print even the most intricate, delicate designs made the BE3D printer the ideal solution for the students’ project. Von Ahsen says, “The quality of the BE3D printer is very, very good. We had three other printers at school – and all the prices were comparable."

“The BE3D printer was by far the best.” The YSoft BE3D printer uses a transparent touchscreen panel and DeeControl software to prepare preprint models. Printed objects of any shape—up to a maximum size of 150 × 150 × 150 mm—can be quickly and efficiently produced using an environmentally degradable polylactic acid (PLA) plastic made from cornstarch. The fully enclosed chassis eliminates external factors affecting print quality, and doors provide easy access to the finished product.

With a fantastic print resolution of up to 50 microns and automatic calibration of the print bed, the students were excited to discover if the Be3D printer could make their vision of a robotic arm and hand a reality. Von Ahsen is thrilled with the printer. “The BE3D printer has a good price for the quality – the quality is top-notch – and it prints rather fast!”

“By using the BE3D printer, we saved between 100 and 200 hours. And doing this project any other way would have cost 20 times more.”

Paul Von Ahsen, Student at HTL 3 Rennweg College of Engineering in Vienna

Benefits

Von Ahsen reports that the BE3D printer was ready to print right out of the box. The students used a CAD software program to develop drawings of all the pieces of the arm and hand from scratch. The BE3D printer enabled the students to create the prototype by printing each piece and then assembling and testing the work before fabricating the final piece in aluminum. “We printed up to five prints for each joint to get our design right. The smooth surfaces the BE3D printer produced were important for the smooth operation of the arm and hand.”

Easy operation and a great design helped the students complete their work quickly. “The printer was pretty quiet, too. Most 3D printers are quite loud,” says von Ahsen. The students were also impressed with BE3D’s technical support's responsiveness.

Not having a YSoft BE3D printer would have been a show-stopper for us. The quality would not have been as good, and the arm and hand joints would not have worked either.

Paul Von Ahsen, Student at HTL 3 Rennweg College of Engineering in Vienna

Their final project was a great success – and von Ahsen attributes part of that

success to the BE3D printer. “I highly recommend the BE3D printer – it has the best quality by far.”